Chiltrix surprised the USA heat pump market with the 2016 introduction of the Chiltrix CX34 ATWHP (Air To Water Heat Pump) with Chiltrix claiming nearly double the efficiency rating of the average system in its class, and higher than the top rated unit by nearly 40%. And official AHRI testing and Certification then confirmed that the CX34 actually exceeded it's "impossible" claims. Chiltrix continues to lead the air to water heat pump class with the CX34 and CX50, together holding claim to both First Place and Second Place in the race for highest efficiency ratings among officially certified heat pumps. CX34 Specs & Performance Data

|

|||

Chiltrix air to water heat pump chiller performance numbers |

|

|---|---|

| In adit ion to AHRI, we also have had our CX50 R32 unit tested and certified by TUV for heating where it obtained the highest possible rating of A+++ |

CX50 Air To Water Heat Pump Spec Sheet

CX34 Air To Water Heat Pump Spec Sheet

|

|

|

|

|

Understand IPLV & Compare to other Small Air Cooled Chiller Heat Pumps - Whitepaper

IPLV Chiller Comparison Chart (shows cooling efficiency of CX34 comparison to leading brands)

The CX-series air to water heat pumps work by cooling or heating a water or water/glycol fluid distribution loop using a high efficiency Mitsubishi DC-Inverter compressor, and pumping the fluid through a system that may include ductless fan coils, hydronic air handlers, and/or radiant systems. Any or all of these types of indoor equipment can be used, and can be used in combination with each other if desired, including domestic hot water. The fluid is returned to the chiller ODU to heat or cool it back to its required operating temperature. The fluid contains water with 0-60% glycol, depending on the location and expected winter conditions. The CX34 uses top=quality German-made variable speed pumps for water/fluid flow control, and of course a variable speed condenser fan. This is not an "evaporative" chiller, it consumes no water and works fine regardless of humidity, performing strong dehumidification as needed. The water/glycol is used to only to distribute heating and cooling between the outdoor unit and indoor units, no water is consumed.

The Chiltrix system uses a DC-inverter compressor and a DC-inverter water pump (both are variable speed) controlled together to achieve the best possible balance of water flow rate and compressor speed. A microcontroller continuously monitors the ∆T between the leaving and returning water, and flow rate, calculates the cooling load, and adjusts the pump and compressor speeds independently of each other to maintain the needed capacity with the lowest possible total power draw. MODBUS Compatible.

|

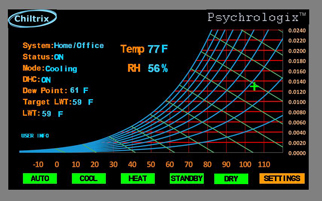

Psychrologix™ Controller - the DHC (Dynamic Humidity Control) function is designed to dynamically control humidity in real time and operate the chiller above its already high efficiency rating. DHC prevents over-dehumidification and wasted energy. The CX34 with DHC dynamically manages compressor speed, pump speed, fan speed, and adjusts its loop temperature as needed to tightly manage humidity and increase efficiency. DHC control allows the chiller to operate well above the IPLV rating at times when humidity is under control, resulting in EER far in excess of the official ratings. See More Details. |

|---|

The CX34 and CX50 ODUs are a complete source of heating, cooling & hot water, With our technology there is no additional supply side needed, although according to your load report you may wish to add integrated dynamic backup heat (V18). You may also integrate with a boiler, solar thermal, solar PV or just about gnathic you can think of. The CX air to water heat pumps are air sourced, and efficiently exchange heating or cooling with the outdoor air, even when it is -15F or 120F outdoors. Wells, other ground or water sources, or cooling towers are not needed. You can use the CX-series air to water heat pump outdoor units with any brand of industry standard equipment including ductless fan coils, ducted or mini-duct type air handlers, radiant systems, etc. We also offer our own ultra-thin DC-Inverter CXI-series fan coil units, air handlers, mini-duct systems, tanks, etc.

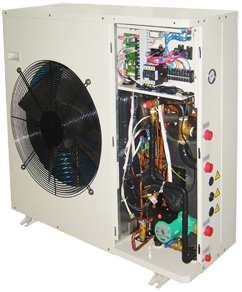

In the outdoor unit we have incorporated the complete refrigeration system including the evaporator, condenser, all controls, valves, etc., as well as all refrigerant into a sealed self-contained outdoor unit. No refrigerant enters the building envelope which is more important than ever as the industry moves towards more efficient but more flammable and toxic refrigerants.

|

|

No refrigeration gauges, vacuum pumps, extra Freon, or special refrigeration/HVAC licenses or skills are needed to install the system. The installer will use basic PEX plumbing and electrical skills. System designs are provided free of charge by Chiltrix.

|

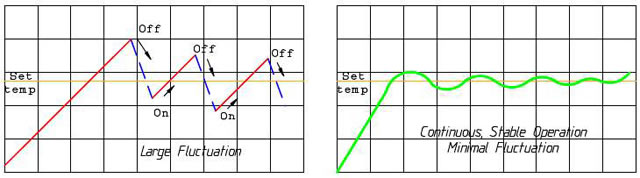

Above left, standard AC unit running at full speed, either on or off. Above right, variable capacity DC inverter unit running to match the load and avoid the on/off cycle. In addition to using less watts per BTU at a given speed, the ability to vary the speed to match conditions saves even more since part-load efficiency is greater than full speed efficiency.

The patent-pending CX-series technology uses a controls methodology that, among other things, accurately matches compressor speed and water flow rate (BTU capacity) directly to the cooling/heating load using real-time dynamic control. In certain implementations, the heating or cling loop operating set point itself may also dynamically change in response to indoor humidity requirements as explained here or in response to outdoor temperatures.

Dynamic & continuously variable control of the Chiltrix air to water heat pumps allows normal operation between LWT 44F and LWT 62F, with an average up to EER 30.72 or higher. Operation is also possible as low as LWT 40F for extreme dehumidification, when needed.

|

|

|---|

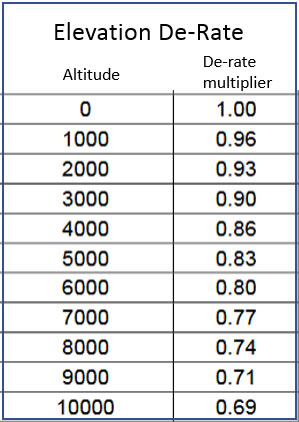

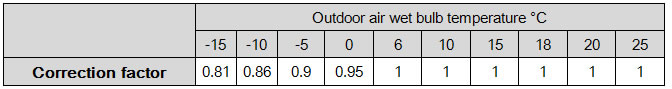

At high elevations, air is thinner and a fan can blow less mass flow (labs. of air). This causes a de-rate of capacity as shown in the chart above-left. About glycol, there is no arbitrary capacity de-rate for adding glycol, however according to the percentages above, the pump speed must be increased to deliver the same BTU. And glycol raises the viscosity. Generally there is a loss of COP of around .0011 per each percent of glycol added. For example, if one started with a COP of 4.0 and added 30% glycol, the new COP would be around 3.968.

Defrost de-rate:

.

All heat pumps must periodically stop heating, run for 1-2 minutes in reverse cycle, then wait a few minutes, and then resume heating. How frequently this will happen is a function of temperature and humidity. The above can be used as an approximate de-rate for high humidity heating conditions. In low humidity there may be little need for defrost. Fortunately, in most locations in North America we see very low humidity in the winter.

All specifications are subject to change. Images are representative only.

|

EPA / ENERGY STAR EMERGING TECHNOLOGY AWARD  |

6 Consecutive Years!AHRI 2018-20203-Year Performance Award 2021-2023 3 Year Performance Award |

World's Record Efficiency

|

Chiltrix CX50 Has Europe's Highest Efficiency Rating! |

Maximum Flexibility:

Heating

Cooling

Hot Water

Radiant (Heating and/or Cooling)

Ductless Fan Coils

Ducted Systems

Mini-Duct

(Concealed Ceiling)

Use any or all of the above together.

Get geothermal efficiency at an air-cooled price.

There is no current ENERGY STAR program for air to water heat pump (ATWHP) chillers. But it is interesting to note the CX34 air to water heat pump chiller exceeds the Energy Star efficiency requirements for variable speed water-cooled chillers (geothermal heat pumps) which are usually considered to be the most efficient type available. See requirements for Energystar labeling of geothermal heat pumps. Chiltrix does not need a well or ground source to beat the geothermal standards!

Air to water heat pump chillers do not use SEER ratings, they are rated based on EER, COP, and IPLV per AHRI 550/590(I-P). IPLV is provided by AHRI for air cooled heat pump chillers. Below, we have applied the AHRI IPLV and NPLV formula to our residential air cooled chiller CX34.

EER = Cooling capacity (kW) / Consumed energy (e.g. electricity) (kW)

COP = Heating capacity (kW) / Consumed energy (e.g. electricity) (kW)

IPLV = The Integrated Part Load Value

IPLV = 0.01A+0.42B+0.45C+0.12D

Where:

A = COP or EER @ 100% Load

B = COP or EER @ 75% Load

C = COP or EER @ 50% Load

D = COP or EER @ 25% Load

The official IPLV EER cooling rating for the CX34 is rated as follows:

IPLV EER = 22.21

CX34 NPLV= EER 30.6, NPLV STC is W55F/A95.

The official IPLV EER cooling rating for the CX50 is rated as follows:

IPLV EER 21.2

CX50 NPLV= EER 30.1, NPLV STC is W55F/A95.

Worlds Records: 1st & 2nd Place!

Of all certified air to water heat pumps,. only the Chiltrix CX34 has higher efficiency than CX50!

For an easy to understand explanation of IPLV see IPLV Explanation & Compare Chiltrix To Top Competitors

Heat can berated is accordance with AHRI 550/590 or under IEC 14825 however AHRI does not itself issue heating certifications. Chiltrix heating performance is certified by TUV. Chiltrix publishes performance under both AHRI 550/590 and IEC 14285.

The rated heating deficiency of the CX34 is tied for first place across USA average climate zones. No AHRI certified unit has a higher seasonal average COP than Chiltrix CX50.

An HSPF rating is like a "SEER rating for heating" however as with SEER, there is no

HSPF certification available for air to water heat pumps under AHRI 550/590, or under any other AHRI standard.However per IEC 14825 there is a seasonal average heating standard for air to water heat pumps, called SCOP (Seasonal Coefficient of Performance). Per AHRAE 90.1 SCOP is converted to HSPF by multiplying the SCOP by 3.412 thus converting it from a w/w value to a btu/w value. Thus in the example of a CX50, its SCOP of 4.55 is equal to an HSPF of 15.51. Note, this is not an official HSPF rating, there is no HSPF available under AHRI 550/590..

Above: Wall mounted fan coil unit.

IDUs connect using flexible PEX water lines. The system is designed to use up to 50% glycol, depending on climate/location. Below is a ceiling mounted CXI fan coil unit.

All of the thin-line (5.1" thin) wall, floor and ceiling fan coil units use DC-Inverter fan motors and run on 120v 60Hz power. Shown below is floor mounted fan coil unit.

See details of our fan coil units here.

EXPORT ONLY: CE Certified

The old-style high-wall fan coil unit shown above uses a standard FCU fan, operates on 208-240V 50/60Hz power.

Shown below - hydronic AHU air handler for ducted central system. CX series air source chillers are compatible with most brands of AHU and hydronic fan coil units, contact us for compatibility and sizing assistance. Ducted hydronic air handlers are available through Chiltrix.

| Hydronic Air Handler Units (AHU) For Ducted Chiller systems |

|---|

|

| SEE Details of our Duct System Air Handlers Here |

Ducted water coil chiller air handler units come in 4 different sizes and use DC Inverter motors for high efficiency.

Mini-Duct Systems

Radiant

Water Heating